With inkjet, there is always a risk of failing nozzles. But the big question is: what is acceptable? One of the readers of this blog recently contacted me. He had a print job that was recently produced on a Landa S10P, but he noticed something strange in a solid black artwork: there were ‘holes’ in it. He asked if I had seen that before. So, I rechecked my most recent sample and compared it with the same image printed with a Canon VarioPrint ix 3200. And indeed, there’s something that looks like failing nozzles. Whether it’s acceptable or not, that’s up to you.

CONTENTS: Failing nozzles | Or something entirely different? | Why is this important?

I must admit that when I checked the Landa sample I got earlier this year, I was only looking for possible registration issues in the black, which I saw in the first sample. I did not check for failing nozzles. I thought that was history. A long time ago, you could see white stripes in print, due to failing nozzles (the nozzles are tiny holes and can get obstructed, e.g., by ink drying in that hole). But time has passed and technology has improved. Every inkjet press manufacturer should be able to handle that kind of artifact to the degree that is acceptable for everybody. However…

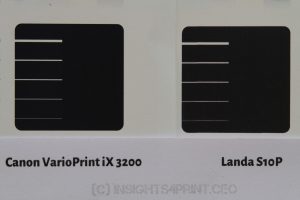

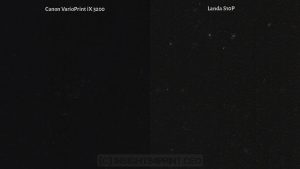

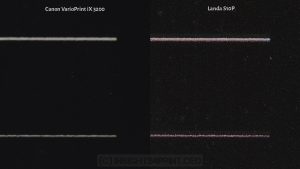

The samples comparing the different technologies, from the Print.com binder I discussed in this article, have a 3 x 3 cm black rectangle. Below you can see several images, first the full size comparison of that black rectangle. Afterwards the regions with the most nozzle failure. Left is always the Canon Varioprint sample, right the Landa sample.

This is a resized version of the full original.

And this is a 100% image of the region with the most artifacts.

I encourage you to look at the full-size image I took! And do enlarge it to 100%, to get a clear view. And don’t forget to set the brightness of your monitor high enough, otherwise you might not see the artifacts in the left part. You choose between a TIFF (124 MB) and a JPEG (30 MB) version of the image.

For completeness, this comparison shows the registration issue I mentioned.

For the record: I made this comparison with a Sony A7R III, with the pixel shift multi-shot mode. This essentially eliminates the Bayer filter by taking 4 consecutive pictures and moving the sensor precisely 1 pixel. The image processing software (Sony Imaging Edge) will combine the four images. Every pixel in that composite image will have true Red, Green and Blue information, eliminating color artifacts due to the Bayer filter (a few years ago, I published a review of this technique).

I exported two pictures from the Sony Imaging Edge software: an 8-bit TIFF, and an 8-bit JPEG (with maximum quality). Imaging Edge does offer 16-bit export. With that pixel shift multi-shot, the composite image contains a lot of color information, but for this case, that didn’t seem relevant to me.

Except for adding some metadata, no changes or corrections were made to the picture. The two print samples were placed on top of each other, the bottom part is just a plain piece of paper which I printed out, so you can identify the two samples. Instead of adding this information in Adobe Photoshop, I did it this way to avoid discussions that I manipulated the original photo.

BTW: when closely looking at the image, you will see that the Canon Varioprint sample has small dots in the white area. Those are ‘refresh dots’, to keep the nozzles open. These can be configured to be placed either across the page (as in this case), or as a ‘refresh bar’ between pages. So, it’s not an error. These dots are there on purpose. And they are just visible with a standard loupe.

Or something entirely different?

There could be another reason for the artifacts in the Landa sample. Someone I showed the image prior to publishing, suggested the following possible cause: an incomplete ink transfer from the belt to the substrate. Could it be that not all nanographic ink is transferred from the belt to the substrate? In case you are not familiar with the Landa Nanographic technique: the ink is jetted on a tranfer belt, where the water evaporates before the ink is transferred to the substrate.

The Landa S10/S10P has a belt cleaning unit, which is revealed in the manual. You can download that manual from the US Federal Communications Commission database. So, the belt at least is/needs to be cleaned. How much cleaning is needed, I don’t know. Maybe it’s just a bit of (paper) dust, maybe it’s a certain amount of ink that’s left on the blanket. If you know, if you have more information on that, please leave a comment! Also, if you have an alternative explanation for what we can see in the images, please leave a comment. I would love to know what’s happening here! And probably many other people in the industry too…

What is certain: the belt adds another variable in the printing process. Another variable that needs to be controlled and managed, making it more complex.

Why is this important?

When you are going to invest in production equipment, you need to be sure it works properly, especially if we talk about investment in the hundreds of thousands, even millions of euros.

When you visit a press vendor and witness a live demo, this will be on a machine that is in perfect condition. It is well maintained, the operators are well trained, they are the best of the best. And they also have a lot of time to prepare jobs, to make sure everything works properly. Which is not necessarily what you will see in a production environment. That’s why you need to order a regular – but challenging – print job at a company that already has that equipment installed. That’s when you will see the real potential of a device, or the real downsides. Getting a job printed will cost you a few dozen euros, but it might save you millions…

PS: I know some people will argue that you shouldn’t look at these samples with a loupe, that the samples look OK when looking at them from an average reading distance. Well, we have always looked at print, at printing technology like that, so why should we stop now? Print will never be perfect, I’ve said that before. But that’s no reason for bad print quality.

Previously published articles on Landa:

The Landa Promise: source material (12/06/2022)

The Landa Promise: Eddy Hagen & Morten B. Reitoft (inkish.tv, 11/06/2022)

The Landa S10P World Record: a closer look at the numbers… (06/04/2022)

Landa Nano Print Quality IRL: inkjet vs inkjet (21/11/2020)

Landa Nano Print Quality IRL: I’m not impressed (15/10/2020)

Drupa 2020: Landa Digital Printing (26/01/2020)

UPDATE 08/06/2024: I took home over a dozen samples from Landa Nano from drupa 2024. Here’s my review (and it doesn’t look that good): Landa Nano, The Good, The Bad, The Ugly.

Be the first to comment