Last Saturday, I visited drupa. And on my list was, of course, getting samples from Landa. Plus, a bunch of other digital printing presses, including one of the other B1 digital printing presses: the Koenig & Bauer Durst VariJET 106. I returned home with samples of both of them. Let’s take a very close look at the samples I took home! One of the last drupa posts from Landa Nano on LinkedIn stated: “Seeing is believing”.

CONTENTS: The Good | The Bad | The Ugly | The Alternative | And some more | The Curious | Why is this important?

Honestly, I didn’t know what to expect from the Landa samples. I receive conflicting information. There are the people publicly praising the Landa presses, the ones you see on LinkedIn, Twitter – oops: X – and in trade publications. On the other hand, I get information, often either anonymous or on the condition of anonymity, that paints a different picture. That’s why I want samples; I want to judge what comes out of the digital printing presses myself. That’s why I made the trip to Düsseldorf.

In contrast to the previous drupa (2016), everybody could pick up many samples. Lots of people threw themselves on the large posters, but when I visited the Landa stand for the first time, there were also some marketing examples (not many, but just enough to take a few). So, I went home with 5 B1 sheets and 5 smaller pieces. When I returned home from drupa, I immediately checked the smaller pieces with my loupe…

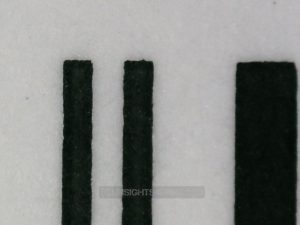

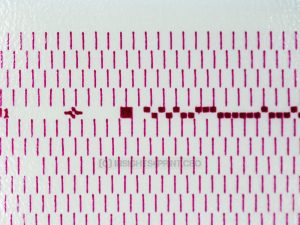

It only took me less than a minute to find the first issue. The first sample I checked was a marketing example with a barcode. And that barcode showed the same issue that has been around for a long time: registration of the black channel, a white line every few rows of black dots. So, for the record, I did not invest hours and hours to finally spot an error. Already the first sample I checked was flawed. I will also include close-ups from other digital printing presses, as a reference.

Next to the samples I collected myself, I also received 4 packaging samples from a friend. A mixed bag when it comes to quality… So, in total I have 14 samples from Landa Nano from their stand at drupa 2024.

(please note that not all images are taken at the same magnification, it depends on what I want to show, when there is a direct comparison, the magnification will be the same)

The Good

But to start with something good: the solids are not ‘contaminated’ anymore! The primaries are nice and clean now. If you don’t know what I’m talking about, check out my first article about the quality of the Landa Nano print.

Added 02/07/2024: what the solids in the solids (in the control strip) look like, seems to depend on the ICC profile used. Fair point, but why did it take almost 4 years before someone from Landa pointed this out?

I’m not sure whether it qualifies under ‘good’, but let’s be generous and put it here: the B1 sheets were coated, protecting it from scratches. Which is a good thing. But more on that later…

One of the packaging samples showed rather good quality, especially the barcode and text.

Suppose you had only seen that one, you would probably believe the story that the Landa Nano presses are excellent machines. But it was only one of them that had that quality… All other samples have issues. And that rather good one, it was flexible packaging, so probably printed on the W11, which is not available yet (and please keep in mind that the W5 and W10 never materialized, even though at least one company bought a W10, in 2016).

The Bad

Unfortunately, this section and the next will be a bit longer than the previous one…

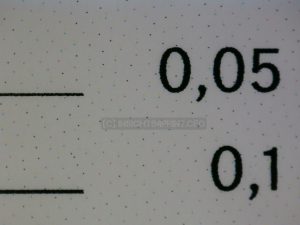

In my previous articles, I pointed out the issue with the registration of the black ink. Between the first and second samples I got, it improved, but it still isn’t solved completely. Seriously? How long can it take to fix this rather basic issue? Others do not have this issue. Just check out this comparison with the Heidelberg Jetfire 50 (their version of the Canon VarioPRINT iX 3200). You can see a slight white space between some rows of drops in the Landa sample (see the orange arrow).

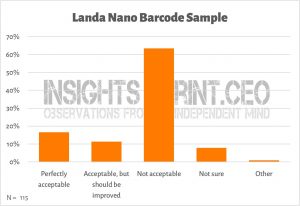

Since barcodes are used very often – especially in packaging – and the barcodes on the marketing samples looked ‘messy’, I put a post on LinkedIn and consulted ‘the wisdom of the crowd’ to check whether this quality is acceptable, or not. The result? The majority – two out of three! – finds this quality unacceptable. Not really the exceptional print quality we are told. “Landa presses enable a new and unmatched standard of high-quality production, agility, speed, sustainability and cost-efficiency.” (from the Landa website, bold is mine)

Added 29/09/2024: there is some discussion about my little ‘wisdom of the crowd’ test. The barcode sample was not a product barcode on a packaging, but a sample barcode on a marketing material piece. According to some that is enough to say it’s misleading. However: what I wanted to point out, is that there still is that weird thing with black lines: the registration, see the orange arrow in the comparison above. Another point of criticism is that barcodes should be evaluated according to the applicable ISO standard, not visually, there is also specialised equipment to do that. And from practice it seems that the standard/the equipment is rather tolerant, so that the barcode above would probably pass. Now, conforming to an ISO standard could that justify ‘bad’ print quality? Not in my opinion (but you may disagree on that). Especially not in packaging: there are also ISO standards for general print quality (among which: color). But many print buyers want narrower tolerances, they want better quality than that. Concluding: you may state that my test on LinkedIn with the barcode was misleading, but you can’t state that the quality of the lines is at the same level as the other sample above. And that’s the point I wanted to make.

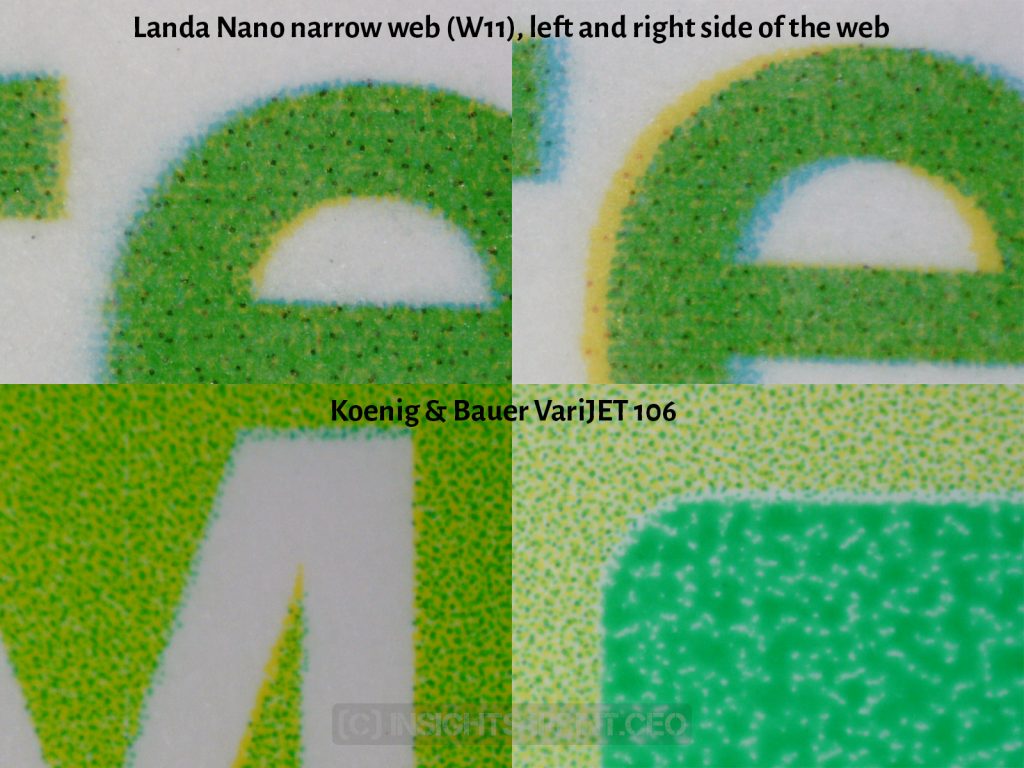

The packaging sample with the nice barcode and text also had something ‘bad’: registration issues. This sample is from a roll of flexible packaging, 48,5 cm wide. The picture below shows two details from the left and right side of the web. One side has a slight registration issue (acceptable, in my opinion), the other side has a much bigger registration issue… For such a narrow web and a digital press, that seems strange to me. To assess whether this is acceptable, later in this article are similar pictures from another digital press at the same magnification…

(added: 29/06/2024: in case this wasn’t clear from earlier in this article: the flexible packaging is printed on the W11, which is still under development; for the record: the W10 was already introduced during drupa 2012, but I’m not aware of any commercial installations of that W10 press, in case I missed something: please leave a comment)

I also noticed a scratch on one of the small marketing examples. These samples didn’t have a protective coating, unlike the B1 sheets.

Now, scratches are not uncommon, therefor the coating that is often applied. But the website of Landa Nano explicatively states: “Remarkable abrasion- and scratch-resistant images”, that’s not what I see. And this is something I also pointed out in my first article, almost 4 years ago. Didn’t they read it? Or don’t they care about critical feedback?

The Ugly

During my visit, I met some old friends from De Grafische Vakpers (the graphic trade press). They mentioned that someone from another manufacturer had noticed banding in some samples on display. One: when you show samples at a trade show, these must be PERFECT! You need to check all of them upfront; they need to comply with the highest quality standards. Otherwise you are sabotaging the message you want to send to potential customers. I already mentioned that before. Two: I knew another thing to check in the samples…

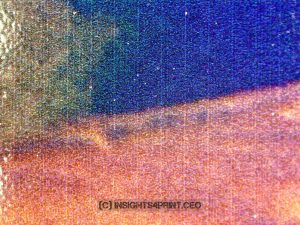

While at the stand, I vaguely thought I noticed banding, but I wasn’t sure. But when I put my microscope on one of the samples… wow, that looked BAD! Please note that the color of the sample is darker than the picture, but the banding is definitely visible when using a loupe or microscope. Plus, with the glossy coating, there is also some reflection.

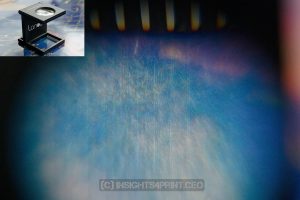

Added 02/07/2024: there have been comments about the image above, that it’s misleading because I used a ‘high magnification microscope’ to make that picture. I did use a microscope, because it’s just easier to create this kind of pictures, but it wasn’t that high in magnification. Check the image below, that’s made via an ordinary loupe, the tool every press operator has at hands. You can clearly see the banding in that picture. BTW: the lines of the ruler you can see at the top of the image are 1 mm apart. And top left is a picture of the setup how I made that picture. With sufficient light (like at a press control), I can even see that there is something weird with that print with my naked eyes.

And after finding the banding you can see in the image above, I rechecked all B1 sheets with large pictures: all of them had this kind of banding in some of the dark parts… It was not just in that one sample, all 4 large pictures showed these.

There’s something I’m not sure about, but if my guess is true, it will fit under ‘ugly’. I have one sample with nice drawings on them. I guess the original was digital artwork, but when looking at the fine lines, they aren’t that sharp… The lines are also surrounded by scattered dots… It looks to me as if the digital artwork was not treated as linework by the RIP/DFE but as a photo. But maybe it could have been a scanned original, it certainly looks like that. What do you think?

Added 29/06/2024: based on feedback from Landa, these scattered dots are already in the PDF. So you can neglect this point, it’s due to an ‘unfortunate’ design choice. As a said before dear vendors: choose your samples at exhibitions, and the design elements on those samples, wisely! If you want to show the strenghts of your equipment, pick design elements that emphasize these strengths.

One thing that’s definitely ugly is what I noticed in two of the (small) packaging samples (the hand sanitizer): what’s up with that dark ink in this picture? That’s not the nice and round dots from the Landa Nano presentations and marketing materials… It even looks like leaking or scattering ink? And since it is uneven spread on the otherwise even background, I guess this is not intentional. What do you think? Does anyone have an idea what this could be?

(added: 29/06/2024: in case this wasn’t clear from earlier in this article: the flexible packaging is printed on the W11, which is still under development)

The Alternative

If you follow the trade press, you will know that the Landa presses are not the only B1 digital presses anymore. There is the Koenig & Bauer Durst VariJET 106 (announced a few years ago already) and the more recent AGFA SpeedSet Orca 1060. Unfortunately, AGFA was not at drupa… The Koenig & Bauer Durst and the AGFA presses focus specifically on packaging, while Landa also addresses the commercial printing market. I have been questioning the use of B1 digital presses in commercial printing already for some time, but I still haven’t gotten a satisfying answer… For packaging, B1 does make sense.

Added 18/06/2024: as someone noted in a comment below, there is also the MGI Alphajet B1. It is also B1 inkjet, but given the much lower speed (1800 sph), it’s in another league in my opinion.

It took me a few visits to the Koenig & Bauer Durst booth to collect samples. The first time, there were none. The second time, there were samples, but only black & white. The third time was a charm: a full-color sample!

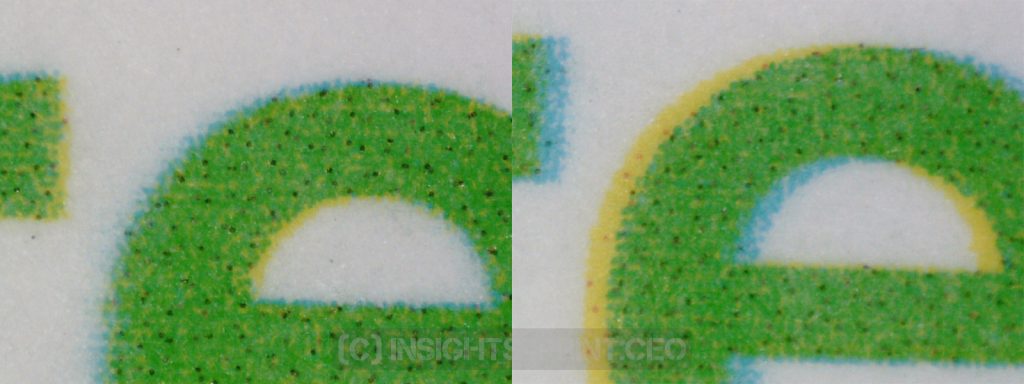

When looking at the overall print quality, I must say that the Koenig & Bauer Durst looks better than the Landa. Below are several pictures, e.g., look at the control strip that is printed along the long side.

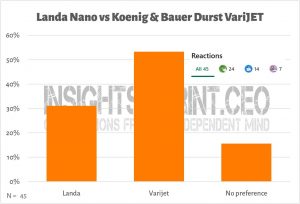

Also in this case I consulted the wisdom of the crowd: I posted several pictures on LinkedIn, without telling which was which, and asked which people preferred. This is the result: just over half of the votes favored the VariJET, about one-third the Landa Nano, the rest had no preference. Now, I do admit that this was a test with limitations: the pictures were small and only a few, the number of participants is low (45). But: if the Landa Nano would have that unmatched quality, it should stick out. It doesn’t. There’s a slight advantage for the VariJET…

But be aware: even though the VariJET looks better, it’s not flawless. I did notice a few failing nozzles and a slight registration errors (please note that the ‘gaps’ you see in the picture of the failing nozzle is due to the reflection of the light my microscope, with a loupe, it’s clean print). However, the errors were less than in the Landa samples.

And some more

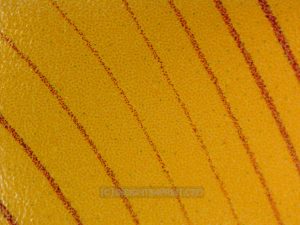

BTW: another sample I got was from the Screen Truepress JET S320, which clearly showed banding. Check the yellow in the picture below.

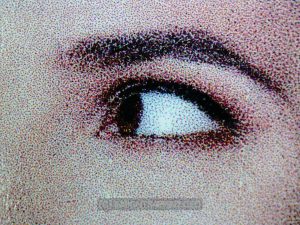

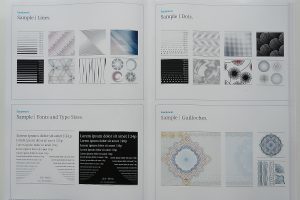

Another digital press I would like to mention, although not B1, is the Canon VarioPRINT iX 3200 and its sibling, the Heidelberg Jetfire 50. I arrived at drupa via the South entrance, via Hall 1. When strolling around the Heidelberg stand, I noticed some print samples with ‘guilloches’, those curly things you see on banknotes and other security prints. I always found security printing fascinating, so I had to check them out. And guess what: they were printed with the Jetfire 50, in inkjet. They already looked great from an average viewing distance, but even with a loupe, they look nice! Maybe not as perfect as in offset, gravure, or intaglio, but really nice lines! Much better than lines on Landa samples… Check them out! BTW: if you detect small dots in the background, those are ‘refresh dots’, to keep the nozzles clean.

The Curious

And I also found something interesting: a flexo-like halo on two different inkjet samples! If you have been involved in printing long enough, you will remember the infamous halo when printing in flexo: darker borders and lighter ‘inside’. Guess what: I noticed this in two samples, one from Landa, and the other from the Ricoh Pro VC80000…

Another curious thing I do not have an answer for is that in some of the Landa samples, there are small impressions in the substrate… kind of like the holes in a golf ball, or little ‘craters’. One of the marketing samples had many of them, that’s where I noticed it first. But when rechecking other Landa samples, several of them had this, especially the ones on a heavier paper (I did not notice it on the B1 sheets with large images, which is a lighter paper than the other samples I have). Plus the two hand sanitizer packages also showed this kind of ‘craters’ (see picture above, the one with the yellow background and dark ink scattered). It’s a bit difficult to see, you need the light to fall at a specific angle to create a shadow. After noticing this, I rechecked all the samples I collected from the digital presses from other vendors, but I didn’t see it in the other samples. If you know what this could be, please leave a comment! I would love to know what this is!

And then there is that last curious thing: why is there such a huge difference between that one rather good sample and the rest? This is not only curious, it’s concerning. This could mean that the quality is inconsistent and that the machine needs to be maintained and adjusted regularly. For example, keeping an 11-meter-long belt within very tight tolerances doesn’t seem easy to me. I have been told that when you get a Landa press, there’s a service engineer on site, all the time, included in the price. For two years according to some sources. It may sound like excellent customer service, but you should ask yourself: why do you need a service engineer onsite, all the time, for one or two years, to keep that one press running? Does that give you confidence regarding reliability and uptime? Especially if you take into account the investment you need to make. We are talking about a multi-million dollar/euro machine.

Why is this important?

If you base your investment decisions on social media posts or trade press articles, the Landa presses would certainly be very high on your wish list. But you shouldn’t (solely) rely on those. You need to test presses yourself, and not only in a demo center. There is a much better option: buy print from someone with that kind of equipment. That’s the best samples you can get, maybe not in terms of quality, but definitely in terms of being representative of what comes out of that press in real life… day in, day out. I guess that’s what some of my samples were: produced by Landa customers, showing the quality in real life.

And when getting real life samples, evaluate them critically, very critically. The investment you are about to make can make or break your company. And that’s why this article is so important: it seems that I’m (almost) the only one who dares to take a critical look at Landa Nano… You should join me and take a very critical look before buying a printing press. No matter which brand, size or technology. This is crucial. This is about the future of your company.

PS: this article is copyright-protected material, I have put a lot of time into it, as I do with all articles. Feel free to link to this article, but reproduction, in whole or even a part, is only possible after prior approval and after paying me a fair price for my work.

UPDATE 19/06/2024: earlier this week Landa sent out a press release about drupa 2024, with “unprecedented Landa orders taken at the show”. A press release that was published by many trade publications. But what does that mean, ‘unprecedented Landa orders’? So, to provide context, I checked the quotes in the artcile above. There is the claim of having had 430 orders during drupa 2012, worth over 1 billion US $. And drupa 2016, that was 450 million euro. So, unprecented could mean over 430 orders, but I find it very hard to believe. We only saw Cimpress at the press conference (who already signed an agreement in 2016 to purchase ‘up to 20’ presses, after succesful testing, now that is ‘multiple presses’), plus the cooperation with Gelato. But no more big announcements… One would guess that if they succeed to pass that 430 orders from 2012, or the 450 million from 2016, there would have been more press releases and announcements. But I didn’t see them. Which leaves me only with one interpretation: that ‘unprecedented’ is a very low number, that would be really unprecedented. And unless Landa Digital Printing starts to be more open about this kind of very vague statements, I will keep pointing to it. Remember, from all those orders in the past, there are only 55 installments (their number from the pre drupa press event), I could only track 43…

UPDATE 15/08/2024: if you are considering purchasing a Landa Nano press, please check the power requirements, the power usage before you sign anything. I received info on that, but I’m not sure if it 100% accurate. But one thing is certain: check this upfront. (BTW: you should always check that, no matter what equipment you are considering)

UPDATE 07/09/2024: the post drupa press release stated Landa Nano had ‘unprecedented orders taken‘. I always wondered what that could mean, ‘unprecedented’. Especially since the bold statements about previous drupa sales. And with a recent blog post by Printweek MENA, we can have an educated guess: around a dozen. At the start of drupa, it was mentioned that they have an installed base of around 60 presses. This new blog post says they sold ‘over 70’ (in general, not specifically at drupa 2024), so that’s around a dozen more between right before drupa and now, 3 months past drupa. And that dozen is unprecedented. Remember, in 2012 over 400 companies signed a LOI and put down money to be on that list. It was over 1 billion $ in orders. In 2016 Landa Nano took 450 million euro in orders. So, a dozen presses, that’s indeed unprecedented… Or, these old numbers were fake. You decide.

Fantastic work hats off to you with an honest hard work.

thank you

Thanks Sean!

Invaluable in-depth analysis backed by real evidence. I can imagine how long this takes.

Thx Michael!

to me, landa looks like a big marketing project that aims at bigger fish to sell itself more expensively, but they know how to make a show 🙂 Great analysis! thank you!

Thx Maksym!

And you could be right… 🙂

Thanks for the analysis Eddy! I was fortunate enough to spend a few weeks installing printers at Drupa before the show and Landa sure made their presence known…

Their technology is interesting for sure but seems to have some ways to go. If I had to guess, the impressions you see on the Landa samples are from their ‘dried image to paper laminating belt’. Not sure if the perfect ink drops they brag about are worth the potential defects and maintenance associated with that belt.

Thx Jacob!

And specifically your suggestion of the source of the ‘craters’ I noticed. The belt is something special… I don’t get it why Landa says their process is simpler than ‘regular’ inkjet, since they have added that belt, which is another variable in the process. And adding variables doesn’t make a process easier. Plus: I’ve heared from different people who know the presses (in real-life that is) that the belt is the weak part. As I found out some time ago: it’s 11 meters long. Try to get that within a very tight tolerance (expansion/movement), which is something you need when printing. Especially if you are applying heat to it.

That chimes with what I picked up from one of the S10P beta sites. If you consider the tolerances required to print repeatably and in good register – thinking more front-to-back here, though your sample analysis suggests that the ‘laid down at the same’ time colour isn’t necessarily all that great either, never mind the craters and gaps – in terms of a percentage of the belt’s length, it’s going to require extraordinary tight control to manage.

I had a conversation way back with KBA who said their solution was a steel belt, for these reasons; they told me that Landa was trying to solve it in software, which seems to me problematic because you’re always chasing errors.

It’s surprising that you didn’t take the time to check out the Alphajet B1 from MGI and Konica Minolta when you presented an exhaustive article on the B1 format inkjet press.

I did check it out while preparing my drupa visit, but given the much lower speed (1800 sph vs 5500 to 11200 sph), I considered the Alphajet B1 in a different league. It wasn’t on top of my priority list during my brief visit to drupa.

But I’ll add it to the article, with the sidenote of the much lower speed.

Also the AlphaJet is a bit of a different beat, as it’s a digital print-and-embellish device

Dear Eddy.

i want to mention something about the fine lines section. Not shure if you find that the drops had a satellite dot besides them. Not only on the scattering, but in the line itself. i’m not shure that could be related to a file proble as they say about the scattering. it looks more related to a jetting problem. do tou find this in this whole print or in any other sample?

Hi Sergi, I got feedback from Landa on that image, the image that was printed looked like that (so: scattered dots in the digital original). And that was only in that part of the full sheet, so it must have been the image used, not the print itself.