You may have noticed that I’m not a big fan of in-person press checks. It’s more about psychology and power games than getting that precious color right. And it’s a waste of resources, both in time and in materials. Fortunately, there are much better alternatives: PRX/PQX and XJDF. PRX/PQX are two ISO standards objectifying the exchange of print quality requirements (PRX) and print quality assessments (PQX). XJDF is an evolution of JDF, now version 1.7. And if you haven’t heard about these yet, take a closer look: more and more brand owners are embracing these…

CONTENTS: PRX | PQX | XJDF | FOGRA ISO-Score | Why is this important?

If you want your print jobs to be executed perfectly to your wishes, you need to communicate those wishes clearly and unambiguously. Communicating your brand colors is best done scientifically: as Lab-values or even spectral values. Project BBCG – A Better Brand Color Guide shows you the way.

But what about print quality and paper quality? What parameters should you communicate, and how? This is where PRX/PQX and XJDF come in. Now, I have to admit that when I started researching and writing this article, I only focused on PRX/PQX, which I have seen popping up several times. It was only at the last moment, when I checked a few things that I came across XJDF and its ability to communicate print quality standards. XJDF needs to communicate more actively about its possibilities in that area…

(as a side note: a long time ago, when JDF was just launched, I was one of the first dozen or so JDF Certified Experts)

PRX/PQX were developed by IDEAlliance, but are ISO standards: ISO 20616-1:2021 – Graphic technology — File format for quality control and metadata — Part 1: Print requirements eXchange (PRX) and ISO 20616-2:2020 – Graphic technology — File format for quality control and metadata — Part 2: Print Quality eXchange (PQX). As with all ISO standards, experts have agreed on the contents, and you can buy the complete standard from the ISO website. Like with all ISO standards, those experts have considered every word to make it as solid and unambiguous as possible.

What is interesting about these two standards is that you can download much information for free! Including sample files… So, let’s take a look at a few of those!

PRX – Print Requirements eXchange

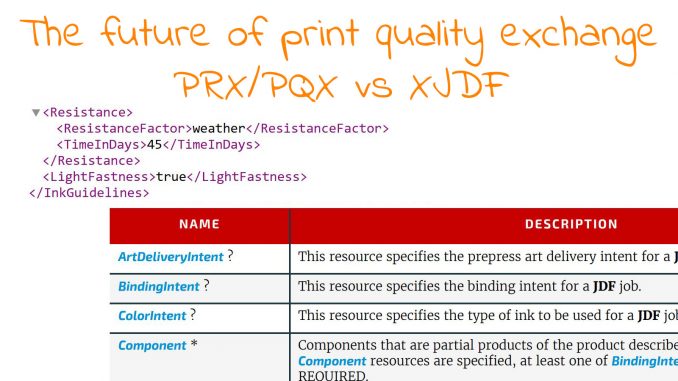

PRX and PQX are based on XML, which means that it is also humanly readable (if you understand computer code a little bit), you can open them with, e.g., a text editor or a browser. Even more important, XML files must be correct (unlike HTML… browsers are very forgiving). Not only structurally correct (e.g., a ‘start’ tag implies that there needs to be an ‘end’ tag also), but it also needs to be checked with a reference, the XML Schema. This schema, e.g., defines what each element in that file means. Let’s check a few from the PRX schema!

This diagram of the top-level element ‘PRX’ shows what kind of information is included:

An important one is ‘BuyerInfo’, which has ‘children’ (subelements if you like), CompanyName and ContactDesignator, to name a few.

EvaluationInfo can carry two fields for the evaluation of the print quality by the print buyer: GradingInfo and PercentAcceptableScores.

QualitySpecification: here it becomes interesting. One of the subelements is ‘QualitySpecName’, where the print buyer can provide a set of words to describe that QualitySpecName. And that might be a flaw: it does not refer to a finite set of quality specifications, like ISO standards. So you can write any text, e.g., “superior quality”. But what does that mean? Your and my interpretation of ‘superior quality’ might be different… That’s a real-life issue that needs to be addressed. More on that at the end of this article!

Another one that might interest you is printMethodType, which belongs to ‘PrintMethod’, a subelement of QualitySpecification. In that element, 12 values are permitted: offsetLithography, dryOffset, flexography, gravure, inkjet, screen, electrophotography, dyeSublimation, letterpress, hybrid, other, any. The last one is used in case you don’t mind which printing technology is used. ‘Other’ is to be used when the printing technology you want to use is not one of the previous ones, e.g., patatoPrinting.

While browsing the sample files you can find on the ISO website, I noticed these interesting elements:

This is part of the InkGuidelines, which is part of the CustomerJob. And you can see that this print job needs to be weather resistant for at least 45 days, plus ‘LightFastness’ is set to ‘True’. This shows that you can put a lot of – sometimes essential – information in that PRX file! And in a standard way…

PQX – Print Quality eXchange

Let’s now take a look at the sibling: PQX. This is intended for the exchange of quality assessment by the printer to the print buyer. This is the replacement of the onsite press approval…

In the PQX element, you can find PrinterInfo, PressRunInfo, InkCollection, and also: SampleCollection. That one provides information about all instances of printed items that were measured… In PressRunInfo, you will find information about the date it was printed, run length, print method, and even the press operator.

When I did a little search in the Schema Documentation, I may have found a flaw in PQX: there is no (explicit) reference to a PRX file… Shouldn’t that be included? It’s in that PRX file that you will find the quality standard that the job should adhere to, information about the printing method, and the required run length.

One of the reasons you should take a closer look at PRX/PQX is that it supports CxF (more on that standard). In PRX, there is the element CxFReferenceData, which is a set of CxF references, so: brand color definitions, used for quality color aims.

In PQX, there is not only that CxFReferenceData again, but also CxFSampleData: the measurements of the printed brand color… And that’s why this is so much more objective than a human press check…

If you want to play a bit with PQX but don’t want to write pure XML, here’s an interesting tool: a plugin to write PQX files in Microsoft Word!

But if you take the support of PRX and PQX seriously, you might want to check the support of this in your quality management tools. Here are a few that mention support of PRX and/or PQX: Chromachecker, MeasureColor, Techkon, X-Rite. If you have other software supporting PRX and/or PQX, please leave more information in the comments!

XJDF

When you are familiar with JDF or the newest version: XJDF, you may have noticed that some of the elements I mentioned above, are also available in JDF, e.g., customer information. JDF has already known the concept of’ product intents’ for a long time, even before PRX/PQX (unless my memory fails). That intent shows what the customer wants, even without knowing all the specifics how it eventually will get produced. Those ‘intents’ will be translated into the actual production information later on. For example, a ‘paper intent’ will be translated into a specific paper. Part 7 of the JDF specification shows the complete list of intents.

And if you, e.g., look into the ‘ColorIntent’ and the subelement ‘ColorStandard’, you will see that there is a limited list of color standards. You can not just specify your own description, it has to come from that list, which eliminates discussions about vague descriptions, which is something I prefer – a lot.

Since the beginning of JDF, the same criticism has always been: it’s enormous! Too big! Well… if you look at the complete specification, the latest versions, that document is over 900 pages… that’s indeed a lot. But that’s also the misconception about JDF: you don’t need to implement those 900 pages, you only need to implement those snippets that you need. And that’s where the Interoperability Conformance Specifications come in (and now try to say that term aloud… 😉). These ICS documents specify which elements you need if you want to communicate between systems A and B about X. And specific for quality communication XJDF has two relevant ICS documents: CusQC (Customer Quality Control) and MisQC (MIS Quality Control). As the name suggests, the first is for communicating quality control information between customer and printer (in both directions), the second is for communicating quality control information between MIS and production. So, XJDF offers functionalities similar to PRX/PQX but in the context of a much larger specification, one that defines and controls everything from customer intent to the most basic level of op production.

FOGRA ISO-Score

Now, I should mention one more thing: PRX/PQX and XJDF are only means to communicate quality information. They do not ‘grade’ it. However, on that front, there is an initiative from FOGRA that could lead to a uniform AND cross-processing way to assess print quality. The project is called ISO-Score, on their website, there is a bit more information.

Given the sometimes (maybe even often) very subjective print quality assessment, that would be a significant step forward.

However, there is one point of discussion: what should be the maximum score? Dr. Andreas Kraushaar from FOGRA launched that question some time ago on LinkedIn: should an ISO-score of 100 be the theoretically ideal print, or should it be based on standards and, therefore, real life? My take: it should be based on standards and real life. If it would be based on a theoretical ideal print, there will be print buyers, brand owners, and others – maybe even some ‘color consultants’ – that will demand that perfect score, without knowing what it represents. They just want the highest score. Just like some people demand a delta E of max. 1. Without a reason or knowing the practical consequences for print production of that demand, we absolutely need to avoid that.

Why is this important?

We have come a long way when it comes to print quality requirements and assessment. In my younger days, there was no standard, universal way to communicate requirements and results. Now, we have multiple options.

In theory, I don’t care whether you pick PRX/PQX or XJDF, as long as you standardize how you communicate print requirements and print quality assessments. But given that XJDF has much more to offer in the same package, I slightly favor that approach.

When it comes to quality assessment, I’m really looking forward to the results of the FOGRA ISO-score project. That would again be a huge step forward: an objective way to assess print quality. One that you can agree upon upfront, making it very clear which score needs to be achieved, one that can be assessed objectively. We really need that.

Great article on the definition and transfer of quality aspects in our industry. XJDF will extend the posibilities of JDF. Did you see what some German print color specialists are doing in this field: https://freiefarbe.de/blog/2017/12/29/erstellung-einer-din-spezifikation/ The information is in the German language. Some information on the freifarbe.de (freecolor) site in in English.

Thx for the link Henk! I will take a closer look at it.