Twenty-twenty is an exciting year for the printing industry: it’s a drupa-year. With a renewed interest in print as a communication medium – something I’ve been advocating for many years – and the introduction of the latest and greatest new technology, it could become a make or break for many printing companies. Making the right choices has never been this important. That’s why you need to read this article: it will guide you through the multitude of fancy, shining stuff you will see in Düsseldorf.

CONTENTS: Three tips | What you will see | Showcase: Landa Digital Printing | Why is this important? | PS: Landa Installments | Updates

As a background: my first visit to drupa was in 1990, that was the one with a record number of visitors: over 440.000! Since that edition, I never missed one. Most years, I spend multiple days on the show floor, hunting for innovations, big and small, that had potential.

But before going into more detail on what you will see at drupa, first three essential tips. One: be very conservative about the timelines shown. Two: take a holistic approach when looking into something new. Three: it’s not only about the hottest new technologies, ‘old’ technology still evolves, old technology fights back.

Timelines have always been something tricky and not only at exhibitions like drupa. The worst case I’ve witnessed from close by was a printing company that wanted to invest in a new workflow system. Since they had a particular workflow, they really needed one unique feature. Vendor A already offered this. Vendor B didn’t offer it yet, but it was on the agenda of the software development and the first version should be released in a few months. Since Vendor B was a lot cheaper (I recall something like 20%), the printing company opted for that one. And guess what: the much needed unique feature was never released…

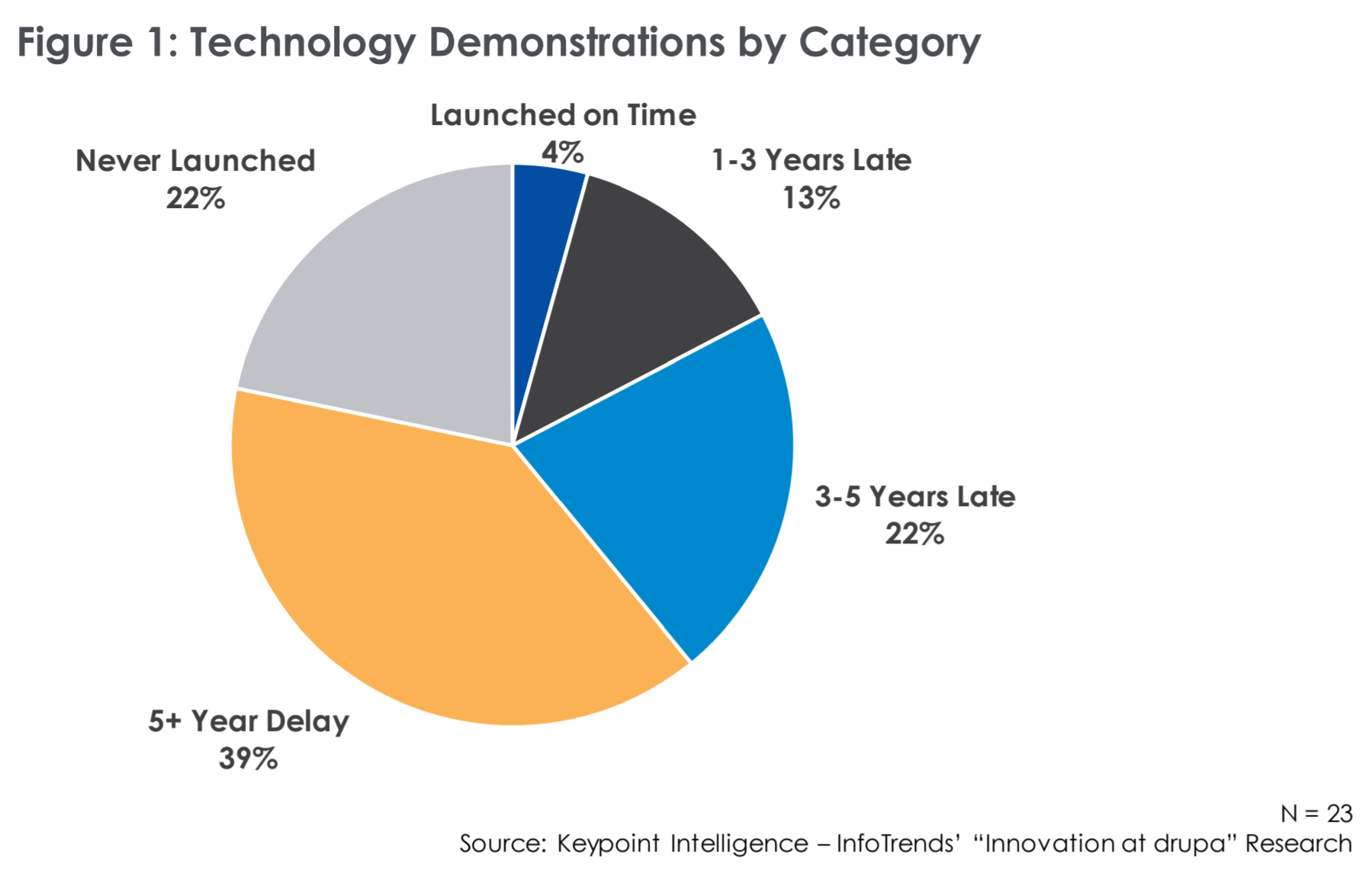

That’s, of course, a rather unique anecdote, but timelines shown at trade shows are dangerous. Last year Keypoint Intelligence wrote a nice report about it: ‘A Balanced Approach – Why Decision Makers Should Resist Hype When Purchasing Unreleased Hardware’. The graph below tells it all.

When investing in something entirely new, you also need a holistic approach: does it fit your jobs and your workflow? Let me show you why this is important with two examples. The first is the breakthrough of digital printing. When did we see a real breakthrough in the market? Not when the specifications of digital presses reached a certain level. Nor when the price point was ‘sub x eurocent’. No, the real breakthrough was when we got finishing equipment that was suited for (very) short runs. Finishing was the bottleneck: traditional folding equipment e.g. had a lot of setup waste. But when your order is only 20 copies, you don’t want to waste 50 or 100 copies to set up your folding machine…

A second example is one I heard a few years ago. It’s about the first waterless web offset press (KBA Cortina). When this was installed and put into production at a Belgian printing company, they soon learned that one element was overlooked: ink that performed well on that kind of machine in a real production situation… It took a long time, and special development by an ink company, before this issue was solved.

And the last advice: ‘old technology fights back’. Don’t forget to look at the mature technologies. E.g., offset printing presses have evolved significantly over the last two decades. Just look at the time needed for job changes. This has gone down from 30 to 45 minutes, to 10 to 15 minutes in a second phase and now it’s ‘on the fly’ (a few minutes). That makes the infamous cross over between offset and digital a moving target.

What you will see

OK, here we go. But don’t expect a list of companies and products (for such a list, check the industry magazines the coming months). No, this overview is more abstract, but also more valuable.

Concepts: these are the ones that will draw attention, that will get a lot of press coverage. But it’s just a concept, an idea what might one time become possible, when both technology and the market are ready.

An interesting example is the Aprion Booknet, which was shown at drupa 2000. It was a machine that would both print (inkjet) and finish (perfect bound) a book. That sounds great doesn’t it? And look at the design! Such functionality in an attractive machine with quite a small footprint! Wow, this is going to change book printing forever! But it was an empty case, I never saw it again. But you can still check this video showing the BookNet!

Technology demonstrations: under the motor hood of every machine, there is some technology. New technology that is beyond the concept phase is often demonstrated, e.g. in a lab-like demonstration. An example from drupa 2012 is Xeikon and its liquid toner technology (Trillium). On their booth they showed one printhead using this technology, to demonstrate the working principle and speed. (depending on the source, this was a real technology demo, while others said it was just a rotating banner to show the concept)

Beta machines, software: this is already a step closer to the real thing, but not yet production ready and still unpolished. This is the equipment, software that’s being tested at a few customer sites, to see if it meets requirements.

There is a danger that the technology fails during beta testing. And it’s still not sure that the equipment, software will make it to the market. For whatever reason. Again, I can use the Xeikon Trillium as an example: they did some beta-testing but right after that, they pulled the plug. Not because they couldn’t get it to work, but because once it would have been production-ready, inkjet would have surpassed it on cost and quality. So they decided to focus on inkjet and their famous dry toner technology. A hard, but correct decision.

Production-ready technology: while the previous steps are interesting to get a broad view of what the future might bring, here it starts to get interesting for your daily production. These machines have been thoroughly tested by the vendor and (maybe) some beta customers. This should be the real deal, or very close to it.

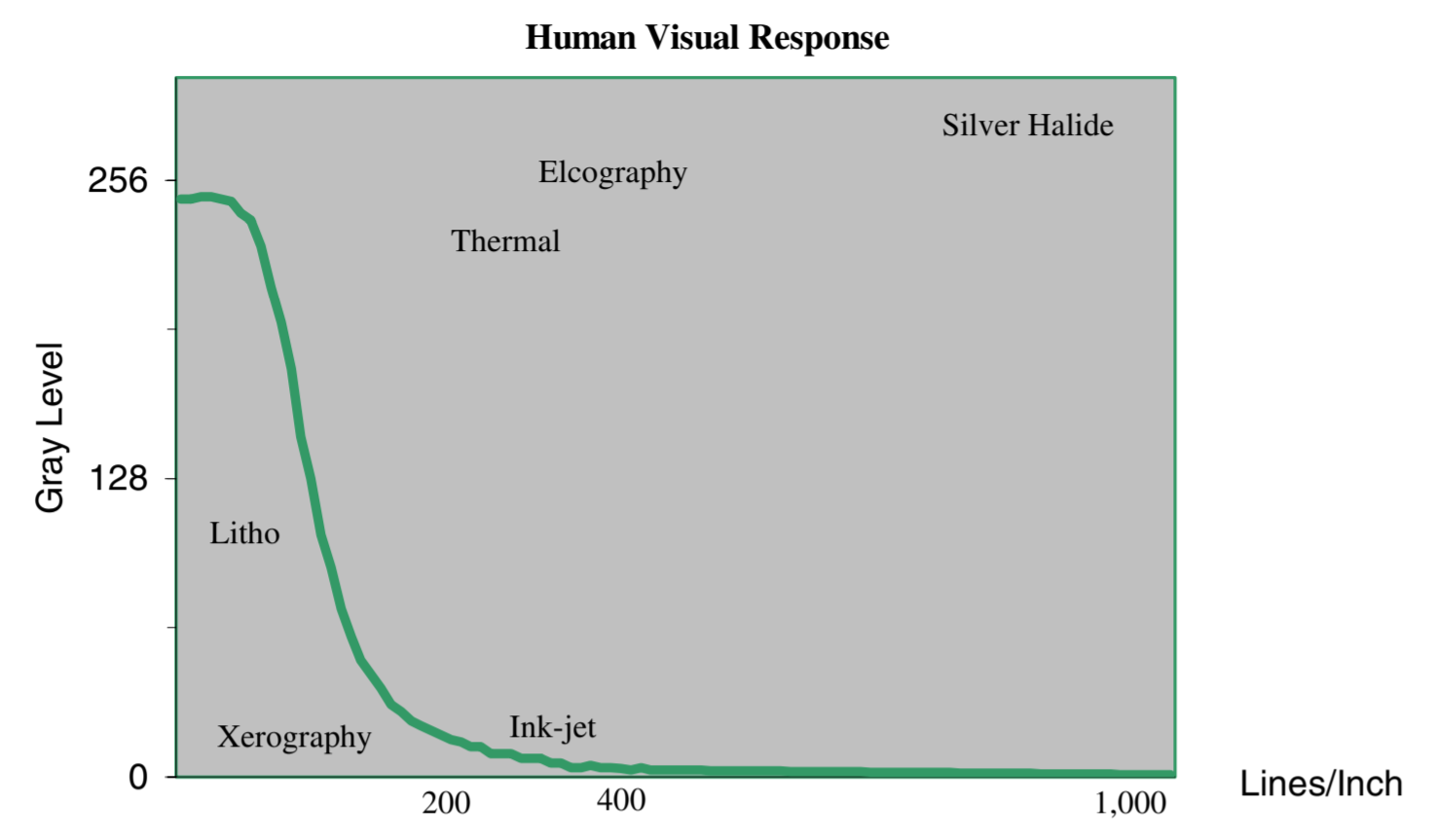

But still, this doesn’t offer any guarantee. Even in this phase, great new technology may fail. E.g. due to the company size and lack of worldwide support. If you have been in the industry long enough, you might recall Elcorsy, a Canadian company and their ‘Elcography’ technology. It was great technology, with exciting applications, but they only sold a few presses.

Another example is the introduction of ‘green films’ during drupa 1995. This was the age when workflows were still ‘computer-to-film’ and with the rising cost of silver and attention for the environment. All major film manufacturers introduced silverless – or ‘green’ – films. They were hot and they were ready. But it didn’t happen. Why? Computer-to-plate. In 1995 we also saw the first generation of CTP, but these machines were very expensive and low quality. They were specifically geared towards newspaper printers. By 2000 that had changed significantly. CTP became much more affordable and better quality. Eliminating the need – and market – for green films.

Mature technology: this is the ‘not so sexy’ part of the show. But this is essential for your daily production. This is the one you can take home from drupa. This is the one that can solve your production issues the day after it’s been installed. I’ve heard many stories the last decade about printing companies replacing two presses with only one new press, sometimes even with extra free capacity left. So, if you are thinking about replacing or adding a printing press, this is where you should look. Not in the ‘hot and new’ part of the show.

Showcase: Landa Digital Printing

There is one company that perfectly illustrates what I wrote above: Landa Digital Printing.

When it was introduced, at drupa 2012, this was nothing more than a concept, with a few samples. But Landa highjacked that drupa. It should have been the ‘on the fly job changes’ drupa, or the ‘flexo goes offset quality’ drupa.

During my visit, I witnessed one of the ‘demos’ several times. And I noticed something strange: the touch screens weren’t responding as they should. Sometimes there was a slight lag, but one time it even reacted BEFORE it was touched… If you ask me, these were regular screens, with a video running, not touch screens. The few examples that were shown behind glass didn’t look that great to me. But still, I did see someone using a loupe to check the print quality…

When I made remarks about this to others and questioned whether the machines, the technology was real, I got fierce reactions: “This is Benny Landa, he knows what digital printing is! This is a revolution, happening right here, right now!” I was almost called a heretic. (well, actually, I was accused of not believing in innovation; in case you’re not familiar with my background: I had been trend watcher and general manager of an innovation center for the printing industry already for a long time…).

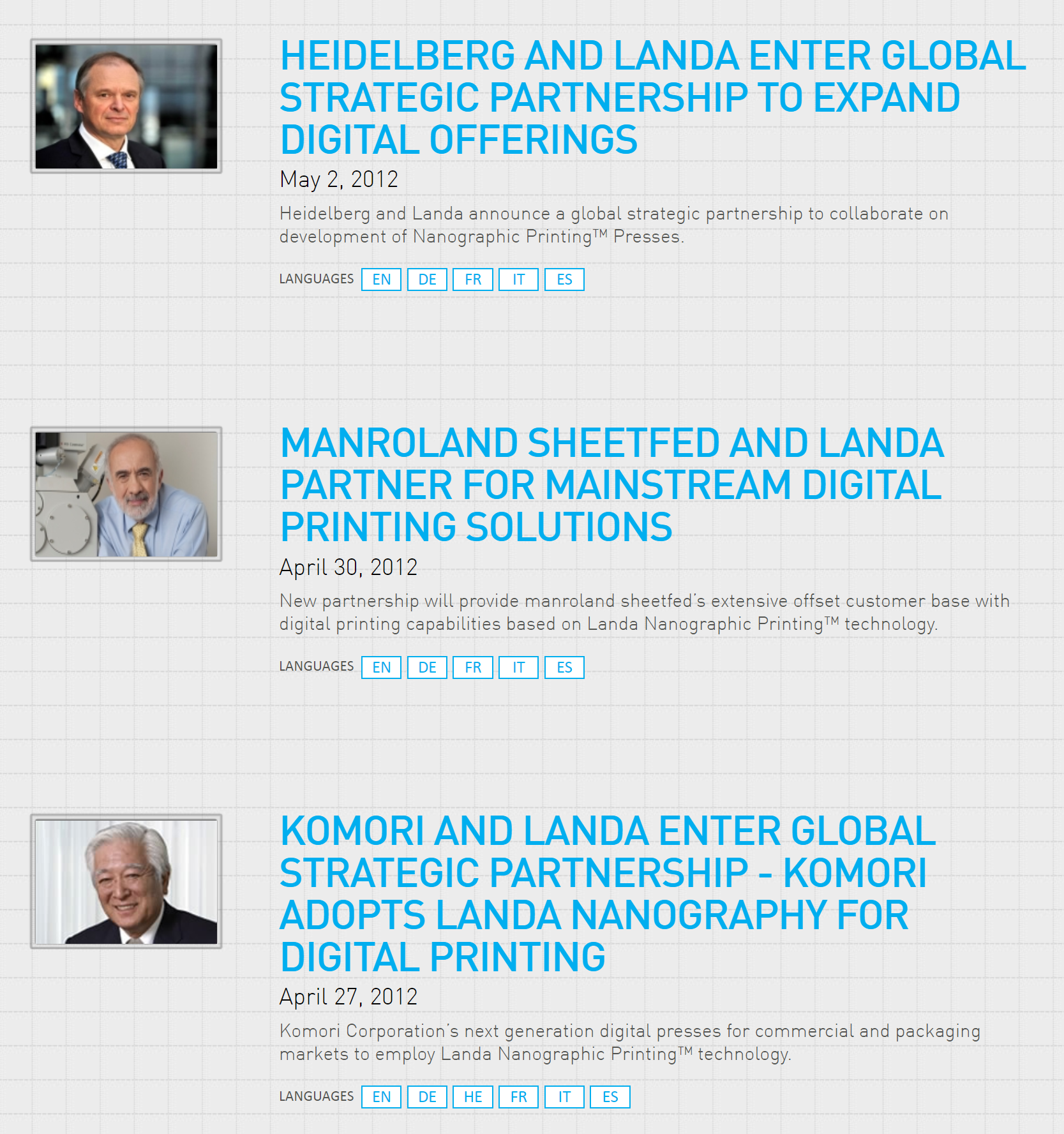

Landa Digital Printing was hugely successful at drupa 2012: over 400 companies signed a letter of intent (LOI) to become one of the first for one of the seven (!) different types of Landa printing presses. And all 400+ paid a deposit. Also many press manufacturers signed ‘strategic partnerships’: Komori, Heidelberg, manroland sheetfed. Everybody wanted to be part of the magic.

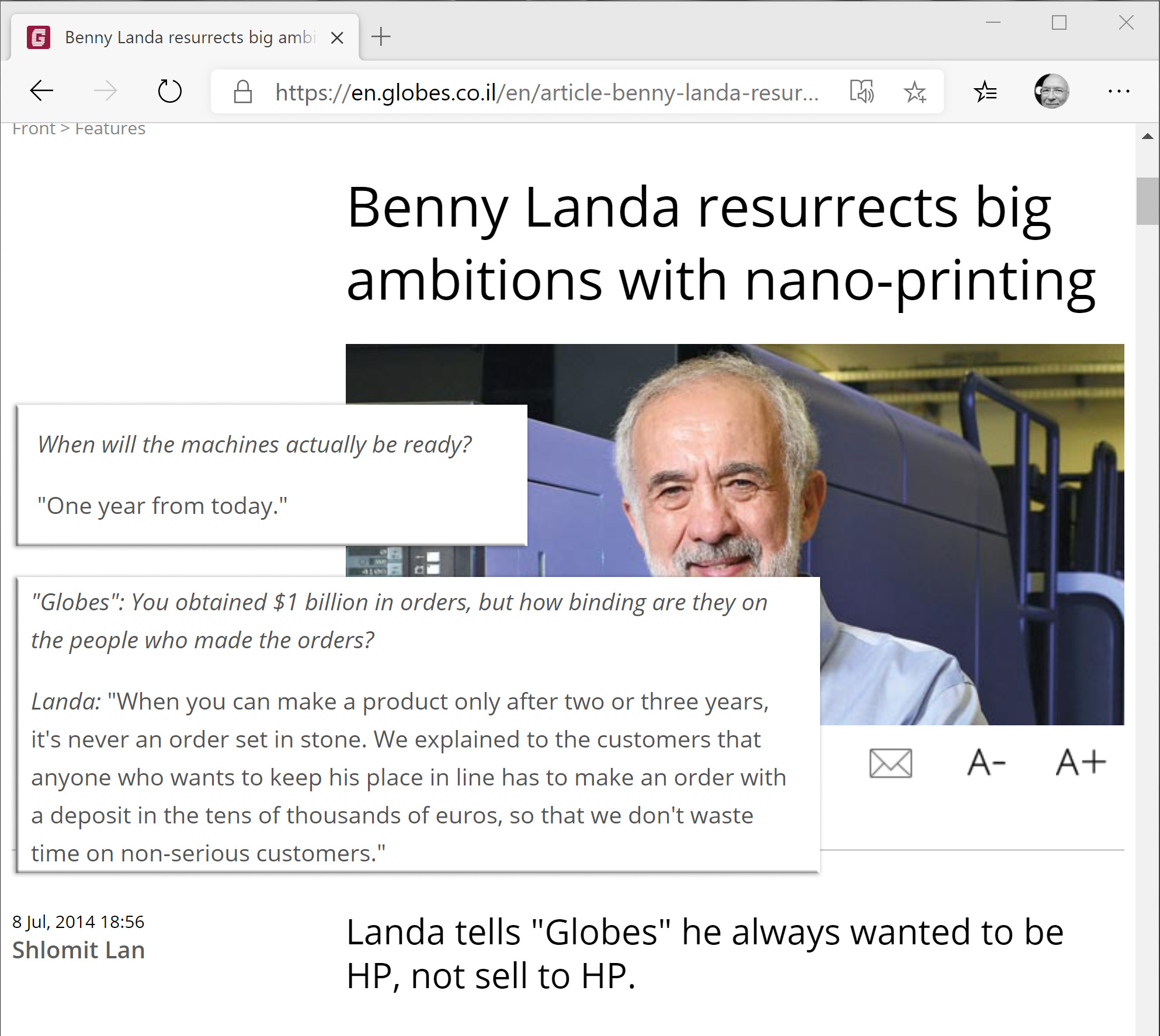

In July 2014, there was an interview with Benny Landa in the Israelian newspaper Globes. It’s an interesting read. Benny Landa firmly claimed that the presses would be ready “One year from today.” The article also stated that “over 4.000” orders had been placed at drupa. I assume somebody made a mistake here: 1 billion US$ for 4.000 orders, that would make the machines rather cheap. And everybody has to stay in line if they want to get a press delivered. (please keep that in mind when you want to purchase one: there might be around 400 companies in front of you…)

(if you want to read more interviews with Benny Landa, please check this overview I created in June 2022)

Enter drupa 2016. The first thing I heard in Düsseldorf, when I ran into somebody I used to know, was: “Landa Digital Printing is real! Cimpress has placed an order for twenty machines!” When I checked the press release later that day, it seemed that Cimpress had expressed the intention to buy up to twenty machines, after successful completion of beta-testing. That’s something very different from ordering twenty presses… So here’s another tip: check the original press releases and read them very carefully.

(update: in august 2021 Cimpress announced to invest in Canon inkjet technology)

UPDATE 28/05/2024: another drupa has started and – of course – on the first day there is a big announcement by Landa: Cimpress has signed a deal for multiple presses (S11/S11P, which run at 11.200 sph, not the original promised 13.000 sph). The brief report from Jo Francis (Printweek) on LinkedIn contains an interesting phrase by Landa: “At Drupa 2016 we expected to ship the first of many presses [to Cimpress] in two or three years but we, Landa, weren’t ready. (…)”. So, that claim to deliver the presses in two or three years (so: 2018 or 2019) is quite revealing: it is absolutely not consistent with the public claims that the presses were ready, or would be ready, first in 2013, then “one year from today” in 2014 (so: 2015). I wonder whether this (new) deal with Cimpress will materialize within the promised time frame (2024).

UPDATE 02/06/2024: you might also want to check this LinkedIn post by Hayco van Gaal from Canon, about their year long cooperation with CIMPRESS, And do look at the comments, especially the one from Michel Hunkeler…

This time there were more and full-size print samples. However, they were behind a rope and in a very dark spot (far away from a P2 and a P1 condition in ISO 3664: Viewing conditions – Graphic Technology and Photography). But still, in these limiting conditions, I could see there were issues with registration. The demo press was also behind a rope and could only be approached by VIPs (which I’m not, although some will argue that I’m a very irritating person, with my coverage of inconvenient studies, tests and bold statements from the past).

What I didn’t hear at drupa 2016 was how the 400+ companies that had signed an LOI responded. (a number of them probably already disappeared)

I guess not that many people noticed, but Landa Digital Printing was also present at the 2017 Interpack trade show, also in Düsseldorf. Not with a large drupa-like booth, but at the Altana booth (which had invested heavily in Landa Digital Printing) and Edelmann, one of their first beta-customers. So I went to the Edelmann booth and asked if I could see samples. Which was, to my surprise, the case… I could check a few small samples. But they didn’t exactly look like the sleek animations in the Landa Digital Printing presentations. When the person behind the counter saw my – somewhat disappointed – face after looking at the print quality with a loupe, the look in return was quite clear: “Yes, we know, this is far from ‘sellable’ quality, there is still a lot of work to be done.”

Yes, I hear you: “But Landa Digital Printing has already installed numerous presses around the world! You can read about new installments almost on a weekly basis!” Well, let’s check the installments. It’s only a dozen (if I’m generous and include the two upcoming installations), the list is at the end of this article. But Landa Digital Printing is very active in the media: every installment is mentioned numerous times. Check their Twitter account to see for yourself. But do read them very carefully: showing interest or testing it is not the same as having a press installed.

So, I will definitely visit drupa this year, to check what’s the state of Landa Digital Printing! And more important: see what production-ready technology one can take home and improve the production, the bottom-line.

Why is this important?

The path between a concept, even the best and brightest ones, and a full production-ready machine or software, is a difficult one. A path that will take at least many years, sometimes even a decade. If the concept ever makes it to the market.

And that’s why you need to know what you are looking at: concepts and technology demos are great for a long-term vision. But if you need to replace a machine or add additional capacity, you need something that works from day one. Please, keep that in mind when you look at all those fancy, shiny new stuff in Düsseldorf…

PS: This is the list of Landa Digital Printing installments to date (latest update: april 2024; in case I missed one, please let me know). It also includes the type of press – only two of the original seven different types are being shipped – and the installation or production ready date that I found on the Landa Digital Printing Twitter-account. You can find all kinds of dates and announcements on their Twitter-account: showing interest, tests in Israel, signing an agreement, making the press ready for shipment, the shipment, installation, first real production and in the ‘reference sites’ also the date of open houses. So read tweets carefully!

(in the past there have been many promises and strong claims, here’s an overview, check yourself if the promises were met…)

- Graphica Bezalel (IL) – S10 (installed August 2017) -> update 03/04/2024: I got an e-mail that this press isn’t there anymore, which would make sense, since another company was the first to reach 20.000.000 flats

- Mercury Print (USA) – S10P (October 2018) -> update 18/11/2022: the press isn’t there anymore, already for some time

- Edelmann Group (DE) – S10 (May 2019) -> update 13/10/2023: two sources claim the press is not productive anymore and/or has been removed

- Virtual Packaging (USA) – S10 (May 2019)

- Route 1 Print (UK) – S10P (August 2019)

- Marketing Alliance Group (USA) S10 (August 2019)

- Schelling AG (CH) – S10 (September (?) 2019)

- ZRP Printing & Packaging (Asia Pacific) – S10 (November 2019)

- Grupo Gondi (MEX) – S10 (Januari 2020) (now WestRock Monterrey)

- Groupe Prenant (FR) – S10P (Januari 2020)

- Blueprint (DE) – S10P (Spring 2020) -> update: installation was completed in June 2021

- Quantum Group (USA) – S10P (Mid-year 2020) -> update 24/03/2023: it seems the press was only installed in November 2022! Original press release (2019), another press release (2022), open house March 2023

- K1 Packaging (USA) – S10 (August 2020) -> update 24/10/2023: a Landa press release from 6/7/2020 says that this press ‘arrives in America’, but this article states the installation was only in February 2021, early 2023 K1 Packaging was in the news again with the Landa press, but that’s still the same press from 2020, not a new one.

- Simian (NL) – S10P (August 2020)

- Duggal Visual Solutions (USA) – S10P (October 2020)

- Em. de Jong (NL) – S10P (April 2021)

- McGowansDigital (Ireland) – S10 (October 2021)

- Hudson Printing (USA) – S10P (December 2021)

- Advantage ColorGraphics (USA) – S10P (March 2022)

- Hudson Printing (USA) – second S10P ordered (May 2022)

- Essentra Packaging (UK) – S10 (May 2022) -> the packaging division was acquired by MM Packaging in June 2022

- Quad (USA) – S10P (May 2022)

- Mitchel Press (Canada) – S10P (August 2022)

- Southern Champion Tray (USA) – S10 (October 2022)

- Abeka Print Shop (USA) – S10P (ordered October 2022)

- Nine Stars Printing (China) – S10 (October 2022)

- Superior Packaging (USA) – S10P (March 2023)

- Primary Color (USA) – S10 (June 2023)

- Brodnax (USA) – S10P (June 2023)

- Sterling Packaging (USA) – S10 (August 2023)

- MODEL Group (Czech Republic) – S10 (December 2023)

- Bluetree Group – second S10P ordered (December 2023, to be installed ‘early 2024’) -> this will probably be updated to the new S11P (mainly higher speed)

- Wirtz Druck/MailingLieve (Germany) – S10P (December 2023)

- NEFF Packaging (USA) – no further details yet, was mentioned in this article (15/12/2023)

- BJU Press (USA) – S10P (installed January 2024))

- Em. de Jong (NL) – second S10P ordered (February 2024)

- ZRP (China) – second S10 installed in ‘H2 2023’, but only announced in March 2024

- FP Mercure / Smilepack (FR) – S10 (February 2024)

- Quantum Group (USA) – S11P (March 2024)

- NEFF Packaging (USA) – ? (March 2024)

- Maqprint Groupe (FR) – S10P (early 2024)

- BPI (Brake Parts Inc) (Mexico) – S10 (installed October 2023 – press release April 2023)

- Wirtz Druck/MailingLieve (Germany) – additional press: S11P (June 2024)

- M13 (USA) – S10P (July 2024)

UPDATE 31/01/2020: yesterday Landa Digital Printing announced that Yishai Amir has stepped down and will be replaced by Asher Levy. Other interesting bits of the press release: Landa Digital Printing claims to employ some 600 people. And, of course: “The company is now poised for unprecedented growth (…)” Which is literally true of course. Growing from 1 installation in 2017 to 6 in 2019 is unprecedented…

UPDATE 13/03/2020: it seems I’ll have to wait a year longer to see with my own eyes if Landa Nano is real: drupa 2020 has been postponed to April 2021, due to the corona / COVID-19 virus. Also today I learned that new customer in the Netherlands, who recently placed an order, expects his press delivered early 2021… That’s about a year after having signed the contract. Please keep that in mind when considering a purchase.

UPDATE 24/11/2020: the wait for Landa Nano samples was not as long as I feared! I recently got the opportunity to get a few pages of my ‘corona photobook’ (with challenging blues) printed on a Landa Nano press. Here is a comparison with a Xerox Iridesse and HP Indigo 7900. And this is a comparison with another inkjet press, the Canon VarioPRINT iX. Conclusion this far? I’m not impressed, not at all. There are other and better solutions in the market.

UPDATE 12/04/2022: here is a closer look at the Landa ‘world record’. The first Landa user passed the 1 million prints per month mark, which is absolutely not impressive given the advertised speed…

UPDATE 12/06/2022: I recently had an interesting online chat with Morten from Inkish.tv. As a preparation for that chat, I checked a large number of old interviews with Benny Landa. With a lot of promises made… Check out the article! You might find it revealing.

UPDATE 01/09/2022: Landa Nano claims a crossover with offset of about 5.000 sheets. An analysis based on the price structure of online printers, including one with a Landa Nano press, reveals a very different crossover: around 200 copies. One online printer recently even claimed 50 sheets is ‘viable’ in offset. Check out the article for all details, how the research on the crossover between digital and offset was done.

UPDATE 14/10/2023: Earlier this week an article was published claiming that there are ‘over 40’ Landa Nano installments, with 6 coming in the next few months. That’s a different number than I have in my list: 30… So I commented on the post, asking if there was a list and arguing that Landa Nano always makes publicity when someone buys a press, when there is a new installement. I’m missing many, if the numbers in the article is right. This was the response to my comment: “Eddy they validated the numbers and I am in no position to pass the information on”. Given the promises and bold claims made in the past (here’s on overview, do check it out), I’m staying skeptical about such numbers, without being shown the full list. Plus: two of the presses in my list, are not there anymore (or at least not active anymore).

UPDATE 12/11/2023: when checking something, I came across this article from Printweek, on the Landa plans to be listed on NASDAQ. This part is interesting, especially the image of where installations should have taken place: “Pre-pandemic, in May 2019, LDP shared its ambitious expansion plans for the number of presses it would have installed around the world in three years’ time, but its roll-out plans have been impacted by the pandemic and by delays shipping some models.

Landa had hoped to achieve a substantial number of installations worldwide by May 2022.”

I tried to find out that origins of that image, I assume it must have been from a prospectus or analyst meeting. But I didn’t find the original source, only this one mention in Printweek.

UPDATE 16/11/2023: Last week there was a new celebration: the first press reaching 20 million flats. Sounds impressive? Not if you check that number… the productivity per hour is rather low. And: is number 16 in my list that was the first to reach this number. Why not one of the older installations? Why not the one that first reached 1 million flats/month? Check out my analysis!

UPDATE 08/06/2024: I took home over a dozen samples from Landa Nano from drupa 2024. Here’s my review (and it doesn’t look that good): Landa Nano, The Good, The Bad, The Ugly.

Great article. The Landa organisation has the best PR-managers in the printing industry. However, as you describe here, they don’t behave like real marketeers, are too eager and publish information that sometimes looks like fake news.

Thanks Henk!

And you are right about their information, one really needs to read if very carefully and check the reality.

Which is also: if what has been claimed is right, there might still be a few hundred companies in front of you if you want to purchase a press at drupa.

BTW: I also wonder what happend to the deal with Elanders, which was supposed to be the first European beta-site.

Just shared your article on LinkedIn.

You carry your “VIP” badge with pride. Don’t you ever stop.

Thanks Steve! 🙂

I believe that the show might be again so much different. All major exhibitions and conferences that I visited in the last 6 months, are using buzzwords like sustainability and personalisation linked to nearshoring, resource sharing with short runs. This is of course ideal for digital printing. Everything needs to be done fully automated and in the shortest time. I see robotization in the printing industry getting serious just to compete at a different level. Finally, there is the risk of automation in the industry, factories are hacked, need to pay ransomeware, in Belgium Picanol was one of these examples and being shut down for a week…the world is changing rapidly and not always positive! I look still forward to spend almost 12 days in Düsseldorf!

Thanks for your comment Peter!

Sustainability and personalisation have been on the agenda already for some time. Hopefully it’s now the time for ‘The Perfect Storm‘ and will they start to deliver.

Automation is indeed very important, even key. But, it’s probably located in the ‘not so sexy’ part of the drupa show. And not only the ‘physical’ automation (machines), but also automation in the digital world, where ‘impossible to be automated’ tasks are now being automated, by RPA (Robotic Process Automation).

Picanol is an interesting example of the dangers of not investing in IT-security and working with outdated systems (e.g. on machines). But there is even a better one, also from Belgium: Asco. They were down for about one whole month! That’s 4 weeks. Some 30 days. Try to imagine what that means to a company, especially a high-tech company. But it’s not new, I’ve written a – warning – blog post about it three years ago. And next to ‘general’ IT security, there is the risk of IoT-devices being hacked. With Industry 4.0 and interconnected devices gaining traction, this will be the next big risk.

To quote a famous song: “You ain’t seen nothing yet”.

I have 41 install locations (not counting any that may have been removed)

Abeka Print Shop

Advantage Color Graphics

Benelux, Royal printing Em. de Jong

BluePrint AG

Bluetree Group

Brodnax

Cimpress

Duggal Visual Solutions

Edelmann

Em. de Jong

Essentra Packaging

Graphica Bezalel

Groupe Prenant

Grupo Gondi

Hudson Printing Company

Imagine! Print Solutions

K-1 Packaging Group

Keystone Paper & Box Company

Koninklijke Drukkerij Em. de Jong bv.

La Galiote Prenant Group

Marketing Alliance Group

McGowans Print

Mercury Printing

Mitchell Press Ltd

MM Packaging

Nine Stars Printing

Primary Color

Quad/Graphics

Quantum Group

Reclameland

Reflex

Route One Print

SCHELLING AG

Shenzhen Nine Stars Printing and Packaging Co., Ltd

Simian B.V.

Southern Champion Tray (SCT)

Sterling Packaging

Superior Packaging & Finishing

Virtual Packaging

ZRP Printing & Packaging

Zumbiel Packaging

Thx anonymous source!

I’ve looked at the list, here are the differences:

Bluetree Group: that’s the same as Route 1

Cimpress: there was of course the big announcement at drupa 2010 (see above), but I have never seen any confirmation that any Landa press was installed at Cimpress, so I don’t count that one. Over the years, there have been more announcements of interest in the presses, but didn’t seem to have ended up in an installment. That’s why I will not count these announcements.

Benelux, Royal printing Em. de Jong = Em. de Jong = Koninklijke Drukkerij Em. de Jong bv.: this is three times the same installation.

Imagine! Print Solutions: I’m not sure about this one… It was announced that Imagine! will become the first North American beta (source), but I didn’t find any follow-up articles or press releases about the installment of that machine.

Keystone Paper & Box Company: there is this article, stating: “Rutt says he hopes to have the press installed either by the end of 2020 or early in 2021.” But when I search Google between 1/1/2021 and today, I can’t find anything new… So this is a question mark for me.

La Galiote Prenant Group: this is the same as Groupe Prenant

MM Packaging: this might be one I missed. I found this YouTube video, but that is, together with a second video, the only reference I found. UPDATE: see the comment below from Elizabeth Gooding: MM Packaging acquired Essentra Packaging.

Reflex: this is an interesting one… They indeed announced the purchase of a Landa press, the W10… (source). But as far as I know, this hasn’t been installed, early Summer last year, the W10 even disappeared from the Landa website… And you know what? In 2012 the same company invested in a W5… (source): “The press will be delivered to Reflex sometime in the next 18 months, (…)”

Shenzhen Nine Stars Printing and Packaging Co., Ltd: this is the same as Nine Stars Printing

Simian B.V.: this is the same as Reclameland (Reclameland is one of the brands of Simian)

Zumbiel Packaging: I can’t find any references for this…

So, to conclude: there are multiple installments listed more than once, plus a few announcements of purchases or even interest in purchases that I couldn’t find any references to the installments. With exception of the last few sales, earlier this year, I don’t want to count the older announcements that didn’t provide information about the installments. There have been too many promises and announcements in the past that weren’t met. Here’s a brief overview.

Eddy – in looking at this further after our correspondence it seems that MM Packaging is the same as Essentra Packaging (announced in 2022 and acquired by MM). We had not reported the Essentra install yet because we were not able to confirm – but will report it as MM Packaging (acquired Essentra Packaging). I would be pleasantly surprised to learn that the company actually has 2 installed in their pharma packaging division.

Thanks for the update Elizabeth!

I did a quick search and on the Essentra website there is more information about the sale of the Packaging devision (do check the file you can download on that page, it contains a lot of information). It seems that Essentra wanted to focus on the ‘Component’ side of their business.